- Products

- Systems

- Tools & Services

News

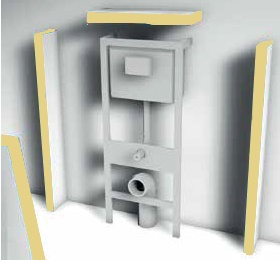

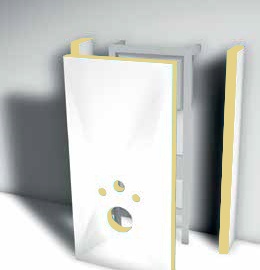

How to easily fit a WC support frame with Atlas Building Board

Owing to the modern technology, the installation of WC support frame is getting easier and easier. In addition, the installation time has also been significantly reduced. Durability, convenience and safety are the most important parameters for the user during household operation – Atlas Building Board not only meets all of them, but it is capable of much more…

A rapidly growing sector of modern building materials offers products, which are often used in completely new and innovative ways. Owing to clever modifications, the performance parameters have improved, the installation has become easier and the installation time has been reduced. All of these improvements result in long-term and failure-free operation. However, durability is not the one and only crucial parameter. Comfort and convenience are not of less importance in long-term use. If one wants to be sure that the material in use meets the expectations, they should definitely choose Atlas Building Board.

For use in bathrooms and steam rooms.

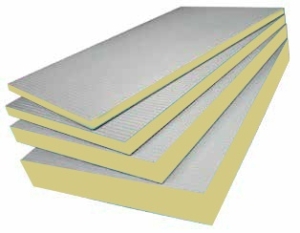

Atlas Building Board consists of extruded polystyrene (also known as XPS) reinforced on both sides with fiberglass mesh embedded in deformable mortar coating based on cement and liquid resins.

Owing to such combination, the Board is characterised not only with high insulation performance (both thermal and acoustic), high flexibility and excellent mechanical parameters, but also full water resistance, which is a decisive factor in rooms with wet zones. Atlas Building Board technology provides us with unique application possibilities, which can be observed in many examples.

Considering the aforementioned characteristics, the ideal intended use of the Board is installation in bathrooms and wet zones, e.g. steam rooms in spa facilities.

Building Boards are available on the market in the following dimensions:

– length: 1.2m or 2.5 m,

– width: 0.6 m,

– thickness: 6, 12, 20, 30 or 50 mm.

Depending on one’s needs, they can choose the Board of appropriate thickness:

– 6 mm – for example, when there must be an even level obtained between a tile and thinner mosaic tile,

– 12 mm – it performs outstandingly when used to level the substrate with an adhesive on full-surface method,

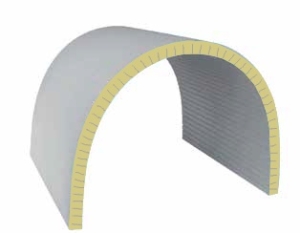

– 20, 30 and 50 mm – it is strongly recommended for various types of built-ins in bathrooms, especially for bathtubs, including semicircular ones. The use of incised Board of this thickness for fitting a semicircular bathtub reduces the installation time to just one hour. Many contractors use Building Boards to construct bathroom furniture of more complex shapes (shelves, bays, tops with support or self-supporting, etc.).

Atlas Building Boards are distributed by Atlas official partners; they are available in the whole range of thickness, both incised (for bending to form circular shapes) and plain.

Why should we not use plasterboards in rooms vulnerable to excessive humidity?

Generally, the use of materials containing gypsum in rooms with increased humidity is not recommended. What is more, if one uses unprotected plasterboards in spa and swimming pools, it is considered as a major mistake. A similar situation occurs when one wants to mount a WC frame. First of all, it is usually installed in the areas of increased humidity. Besides, water may find access to the board, which will definitely cause a serious problem. Based on the experience, we can say that the degradation of gypsum materials occurs already after several years since installation. Some contractors protect the plasterboards against adverse effects of moisture with liquid damp proofing materials applied upon the boards. Unfortunately, they apply the membrane only upon one (inner) side of the board. It does not eliminate the problem of water soaking by the plasterboard. Water may still penetrate the partition also from the outer side (for example due to any flaw in partition tightness). Increased humidity in the built-in may result also from water vapour condensation process. This is the effect of temperature difference and frequent exchange of water in the tank located in the frame. This phenomenon intensifies on hot summer days, but it can also occur in winter-time when water in use is much warmer than the temperature outdoors. Water vapour condensation on mirror, window or other cold surface, including the tank with cold water for flushing the toilet, is the visible result of the phenomenon. Another proof for condensation is water vapour condensation on the tiles surface in the area of the tank. Keep in mind that the same thing happens to the other side of the surface – the one which is not visible. Some contractors, with the aim of preventing this undesired effect, try to protect the lining by mounting two layers of plasterboards. In result, they decrease the superficial condensation risk on the tiles, but on the other hand, the risk of vapour soaking inside is increased as there is more unprotected gypsum material than before. One should also remember that in case of increased humidity, unprotected areas close to pipes passages or flush buttons are vulnerable to potential condensation.

Advantages of built-ins with Atlas Building Board

Mounting a WC frame with Atlas Building Board rather than with traditional plasterboard provides the contractor with a great deal of advantages:

1. It performs way better than traditional plasterboard in rooms with increased humidity. Due to its water resistance and very good thermal characteristics, it ensures durability and completely eliminates adverse effects of water vapour condensation. It has also the ability of soundproofing any potential sounds resulting from filling the tank with water.

2. Easy installation –incomparable to other systems. The Board is very easy to work with, so that one can easily perform any shape of built-in, from right angles to semicircular shapes.

3. Lower costs and faster installation time – difference in cost between mounting the same elements with Atlas Building Board and traditional materials definitely favors the first solution.

4. Durability – elements made of Atlas Building Boards are characterized by large load capacity and rigidity. One can use Atlas Building Board to form tops, shelves or seats.

|

Flush-mounted WC frame with Atlas Building Board. Step by step installation Necessary tools: pocket knife, gap filling adhesive e.g. WIM Strong, screws, tape measure, screwdriver. STEP 1. Measure the front Board. Match the front Board with the holes in the WC support frame. WC support frame must be properly fixed to the wall and floor. STEP 2. Having considered the floor finish level and final height of the whole set, cut off the material excess. STEP 3. Mark the place for the flush button on the front Board. STEP 4. Apply gap filling adhesive (e.g. WIM Strong) on the frame side edges and press the Boards against them. STEP 5. Apply zincked backing rings on the screws every 20 cm so as to strengthen the connection between the Board and the frame. STEP 6. Mount upper Board in an analogous way (see steps 4 and 5). |

Original text: Marek Jabłoński, WiM, ATLAS Group

English text: Piotr Marciniak, ATLAS Group