- Products

- Systems

- Tools & Services

News

M-System + tape = successful duet

Proper joint between plasterboards mounted to the ceilings or walls is an extremely important element when using ATLAS M-System technology. Reinforcing tapes are indispensable to ensure safe use of gypsum finish. We would like to present useful tips on how to strengthen the structure of the boards in M-System technology.

From the user’s point of view, a durable and aesthetic joint between plasterboards is extremely important in any drywall technology solutions. In the event of an installation error, building settlement or other loads following the building operation, scratches or cracks can appear on the walls or ceilings, which can completely ruin the final visual effect.

Joint between the plasterboards – installation

There are several ways to make a proper joint:

1) Without a tape

The joint between plasterboards can be applied only with the use of Atlas Filling Gypsum for the joints filling. However, this solution has some limitations, namely, the edges to be jointed must be factory-cut, i.e. cuts on the construction site are not permitted.

2) With a tape

The second solution involves the use of reinforcing tapes. The boards cut edges must be first beveled at an angle of 45° and then primed so that the board does not absorb water during and after the gypsum application. Next, the first layer

of gypsum is applied, the tape is embedded and finally the second layer of gypsum is applied.

Nowadays, there are several types of reinforcing tape available:

– scrim tape – square mesh

– fleece tape – fine fibres mesh

– paper tape

– tuff-tape

Which tape to choose? TEST

One can come across several different opinions on the appropriate method for joints reinforcing. We are going to present an independent academic studies carried out in Lodz University of Technology*.

Course of study

– Scientists from the University of Technology carried out a laboratory test consisting of four-point bending of joints between plasterboards. The purpose was to simulate as accurately as possible the movement of the board joint without any additional support. Such simulation reflects the situation which takes place between the discs in M-System technology.

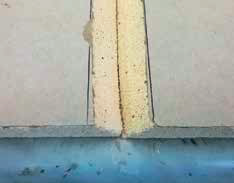

– Two plasterboards: 200 x 300 mm each; with edges cut and manually beveled at an angle of 45° (Photo 1) were used to form a plasterboard panel. The beveled surface was primed, jointed with gypsum and reinforced with

tapes according to the technology. The samples were then stabilized for 7 days at 23°C ± 2°C.

– A strength machine ISTRON 3384 was used for testing. It measured the strength and the joint deflection until the scratches appeared on the panel surface (Photo 3).

– Five aforementioned technological solutions (one “no tape” and four solutions with different tapes).

– To minimize the measurement errors, there were three tests carried out for each jointing method. The average joint strength results are presented in the Table 1.

A joint prepared for testing.

The jointing tapes to be tested. From the left: scrim tape, fleece tape, paper tape, tuff-tape.

Test methodology.

|

No. |

Material |

Damaging force [N] |

Deflection [mm] |

Resistance to bending [MPa] |

|

1 |

Filling Gypsum |

130.1 |

0.7 |

0.83 |

|

2 |

Scrim tape |

371.4 |

2.1 |

2.38 |

|

3 |

Fleece tape |

462.9 |

3.1 |

2.96 |

|

4 |

Paper tape |

492.6 |

3.5 |

3.15 |

|

5 |

Tuff tape |

585.7 |

5.9 |

3.95 |

Tab. 1. Results of strength tests for different plasterboards joints.

* PhD Eng. Piotr Konca, PhD Eng. Marcin Koniorczyk, prof. Lodz university of Technology, “Overview and properties of materials for reinforcement of gypsum board joints”

Conclusions

The results have confirmed contractors’ general observations regarding the joint strength between plasterboards depending on the type of tape:

– in each case it was a board to crack not the gypsum joint,

– in case of tapes use, the scratch was mostly transferred throughout the whole cross-section of the board,

– only the tuff-tape did not allow the scratch to go through the tape.

Scratch examples: the scratch is within the board not at the gypsum joint.

Only the tuff-tape did not transfer the scratch (see red arrows).

Why tuff-tape is better than other tapes?

Above all, it is stronger and does not transfer the scratches to the board surface. It is due to the fact that the tuff-tape is made of several components. The core is made of white, flexible and crack-resistant membrane made of hard plastic (usually ethylene and vinyl acetate copolymer). It gives high tear resistance up to 9.0 MPa. The core is covered on both sides with cut textile fabric (wool or cotton), permanently bonded to the substrate with latex glue. It allows us to cover the tape with all types of filling gypsum, paints etc. The perforated part of the tape allows the mass to penetrate. Mass and absorbent and rough tape improve the adhesion to the substrate and the joint durability.

There are two types of tuff-tape available:

– 0.25 mm thick – used for joining boards and inner corners,

– 0.35 mm thick – used for joining boards and inner corners as well as outer corners.

The small tape thickness makes it easier to cover the tape with a thin layer of filling gypsum which dries quickly and can be grinded easily.

Tuff-tape outruns the traditional tapes in other respects. It has a similar stiffness in all directions, not just one, in comparison to the fleece tape and scrim tape. Therefore, it makes the second gypsum application safer as there is no risk of moving or corrugating freshly installed tapes. When compared to the paper tape, it neither wrinkles nor produces air blisters under the tape – these effects are caused by uneven moisture penetration.

Test results summary

ATLAS M-System technology requires the joints between the plasterboards to be reinforced with tapes,

regardless of the edges finish – whether the edges are pre-cut or not. We recommend using fleece, paper or tuff-tape when M-System is in use.

As the results of independent tests show, the tape tuff-tape meets the most demanding contractors’ requirements. It is not possible to form a scratch on a visible board surface when using the tuff-tape. This feature will meet the expectations of every investor.

Only the tuff-tape allows 60 x 60 cm spacing between the disks with single plasterboard layer technology.

Original text: Mariusz Jurkiewicz, ATLAS Group

English text: Piotr Marciniak, ATLAS Group