- Products

- Systems

- Tools & Services

News

Salta S – state-of-the-art façade paint

Everybody awaited such paint – not only customers, but also contractors. And finally it is available in Atlas portfolio! It is called Salta S and it is a truly silicate paint. Before introducing to the market, the paint was subjected to thorough testing and it performed superbly.

Salta S is based on mineral binder (potassium glass) enriched with polymers (in the form of hybrid silica binder). These technology provides the paint with unique physical and chemical properties, excellent operating parameters and, above all, long-term durability. In other words, technical and aesthetic parameters keep the same for very long time.

Mineral character of the paint results in:

– the highest water vapour permeability – twofold effect: the wall can “breath” and there is no moisture accumulation inside. We also recommend this product on façades of heritage buildings and buildings under renovation, on renovation plasters;

– no cracking or peeling from the wall under static load and deformation due to thermal load (owing to chemical bonding between the paint coating and the substrate);

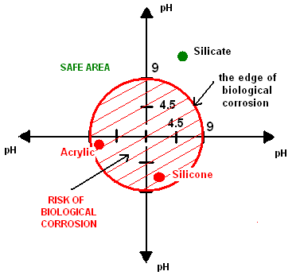

– resistance to microbiological corrosion: mosses, algae and lichens do not occur on a wall even under extremely difficult conditions and in the most demanding locations (close to forests, parks, meadows, water reservoirs) – high PH of the product protects the surface against biological corrosion;

– shorter technological break between façade works, thereby it is possible to reduce the time needed for a particular façade work phase significantly – fresh mineral renders may be painted already on the third day after application

with no risk of efflorescence appearance;

– low content of volatile organic compounds (VOC); the paint does not contain any substances harmful for human beings or environment and can be used indoors.

Table 1. Basic parameters of Salta S.

|

Parameter |

Value |

|

Diffusion resistance coefficient Sd [m](1) |

≤ 0.02 |

|

Superficial absorption W [kg/m2h0.5] (2) |

< 0.14 |

|

Water vapour permeability V [g/m2 x 24h] |

> 150 (high) |

|

pH |

11.8 |

|

Gloss (60°)(3) |

2.2 (deep matt) |

|

Number of colours |

352 |

|

VOC [g/l] (4) |

22 |

|

Consumption [l/m2] |

approx. 0.2 |

(1) Since it is an extremely low number for a paint, the wall has the ability to “breath”.

(2) Low water absorption means that the surface is protected from excessive water soaking, thus it does not provide favorable conditions for the development of biological life, surface degradation and dirt.

(3) There are three classes distinguished: matt, half-matt and gloss.

(4) The standarised maximum amount of VOC for interior paints given by the appropriate standard is 30 g/l. This means that Salta S paint can also be used indoors.

Drawing 1. Possibility of biological corrosion in relation to different type of façade renders.

Figure 1: Silicate renders are not vulnerable to biological corrosion due to high pH. In order to prevent acrylic and silicone renders from corrosion, one should protect them with biocides.

Inorganic pigments – durable colour

The paint contains carefully selected inorganic pigments only. The colour range is smaller comparing to, e.g. acrylic palette. However, the use of the most durable pigments provides long-term resistance to damaging UV action and colour durability.

Polymer additives – protection against moisture and dirt

Typical silicate paints are characterized by higher absorption when compared to silicone and acrylic paints. The solution implemented in Salta S – use of additional resin and superficial hydrophobic additives allowed to reduce the paint absorption. It protects the substrate against rain and moisture or dirt ingress.

|

Pros and cons of SALTA S |

|

|

FOR AN INVESTOR |

|

|

RESISTANCE TO BIOLOGICAL CORROSION – due to high pH, the paint is not vulnerable to moss, algae and fungi; the façade keeps its original appearance for many years. |

Limited colour palette – inorganic pigments used in the paint, therefore it is impossible to obtain some intense tones of e.g. red and green. If one would like to obtain intense red or green, we recommend using SALTA E (1094 colours, including intensive ones). |

|

COLOURS DURABILITY – pigments are resistant to UV radiation and alkali. |

Suitable only for mineral substrates – the paint cannot be used for renovating surfaces coated with dispersion products, e.g. acrylic render. |

|

STRONG BONDING TO THE SUBSTRATE – the paint does not crack or peel from the wall . |

|

|

FOR A CONTRACTOR |

|

|

FAST-PACED WORK – painting fresh mineral renders is possible already after two days since the render application. Thus, the technological break and time of use of scaffolding is short. |

Vulnerability to weather conditions during application – there is a need to protect the façade with protective mesh during painting; the paint cannot be apllied on very hot and sunny days. |

|

CONVENIENT PACKAGING – oval shape of the bucket is suitable for the most commonly used rollers for façades painting – it enables the workers to get the paint directly from the bucket (it fits a grid for painting and a roller 25 cm wide). |

|

|

REMEMBER Properties of silicate (silica) paints: – Contain water glass, mostly potassium, which arises in result of melting quartz sand in high temperature. Sand contains a lot of silicone with potassium oxide. In result, silicate paints have a different method of bonding in comparison to dispersion paints. – They form durable and uniform system with the substrate. It is due to reaction between water glass and carbon dioxide contained in the air. The reaction results in the bonding process (silicate paint penetrates into the substrate structure) between the paint and the mineral substrate. – Perfectly reflect the texture of the substrate. Tight bonding with the substrate prevents from cracks and peeling from the wall. The coating forms matt finish and reflects the substrate texture. – They are permeable (they have low diffusion resistance) – carbon dioxide or water vapour can easily penetrate the painted wall. Thus, silicate paints can be applied on heritage buildings and used in renovation works. – They are resistant to biological corrosion. Owing to very high product alkalinity (pH > 10), the surface is protected from development of algae and mosses, and keeps aesthetic appearance for many years. – Pigments contained in silicate paints are resistant to alkali. Due to high pH, silicate paints are coloured with inorganic pigments resistant to alkali. Therefore, the palette of colours is slightly smaller than the one offered by other dispersion products. Nevertheless, this solution is the most resistant to UV radiation. |

TEST: Comparison of selected silicate paints

Before we introduced Salta S to the market, we had tested many recipes in order to create a paint of state-of-the-art technical and operating characteristics. We conducted validations not only at our training academies in Zgierz and Dabrowa Gornicza, but also at actual construction sites. Based on the information from contractors, we aimed to create a product which would be easy to work with and which would have all outstanding technical parameters. We compared the final result with the most popular products on the market: Ceresit CT 54 and Caparol Capatect SI-130.

The test was divided into two parts:

1. Practical part which consisted in the assessment of the operating parameters during application upon freshly applied mineral render of 2.0 mm aggregate size. The paints of similar colours were used: Caparol SI-130: Curry 115, Ceresit CT 54: Dakota 2, ATLAS Salta S: SAH 0008). There were two coats applied. The technological breaks recommended by manufacturers were kept. We assessed the following parameters:

– opacity,

– odour intensity,

– splash during application,

– ability to flow and fill the intergranular spaces.

2. Laboratory, where the following technical parameters were checked with the use of special equipment:

– opacity (at coating thickness of 100μm),

– pH,

– viscosity,

– gloss,

– time when dust no longer adheres to the painted surface,

– flow,

– coating texture.

1. Practical test

The first part of practical test showed that none of the tested paints coated the substrate sufficiently with just a single coat – there was always the second coating needed. Each paint splashed and got the painter a little dirty during painting, but it was Caparol which splashed the most. This result was surprising, as the paint had really thick consistency, moreover, its appearance in the bucket was highly evaluated by the auditors. Caparol was also determined as the paint with the most intense “ammonia” odour, which in the opinion of some may cause serious problems during long-term work. The least onerous in this aspect was Salta S. Ceresit did not present good spill in the intergranular spaces and left a lot of areas unpainted. In the opinion of auditors, the roller was led smoothly in case of Salta S and CT 54, on the contrary there was a little drag when painted with SI-130.

After the second painting, it turned out that Ceresit paint had the worst opacity and there is the third coating needed. ATLAS and Caparol paints coated the substrate completely.

Table 2. Comparison of parameters: ATLAS Salta S and competitors.

|

Parameter |

Ceresit CT 54 |

Caparol SI-130 |

Atlas Salta S |

|

Opacity – I coating |

x |

xx |

xx |

|

Opacity – II coating |

xx |

xxx |

xxx |

|

Odour intensity |

xx |

x |

xxx |

|

Splashing |

xx |

x |

xx |

|

Flow/ability to fill intergranular spaces |

xx |

xxx |

xxx |

x poor xx average xxx good

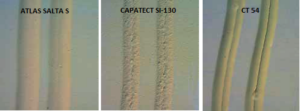

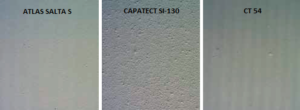

2. Laboratory test

The testing conducted in the laboratory confirmed all the observations from the practical test. The highest opacity was obtained by ATLAS paint, a little lower by Caparol, while Ceresit presented clearly lower results in this matter. High viscosity of Caparol made it harder to lead the roller. The weakest flow applied to CT 54 – it is easily seen in the pictures taken with the microscope. The pictures show also the “rough” structure of SI-130 paint which may favor dust settling on the façade. The highest pH, and thus the strongest protection against biological corrosion was presented by Salta S. However, it should be noted that all of the tested paints had the alkaline pH of above 9 – this means they are placed in the “safe area”, in other words, in the environment in which the development of lichen and moss is extremely difficult.

Table 3. Comparison of laboratory parameters of Salta S and competitors – laboratory test.

|

Parameter |

Ceresit CT 54 |

Caparol SI-130 |

ATLAS Salta S |

|

Opacity [%](1) |

93.54 |

98.05 |

98.39 |

|

Gloss 60°n(2) |

2 |

1.8 |

2.2 |

|

Viscosity(3) |

14500 |

19200 |

10000 |

|

pH |

10.4 |

11.2 |

11.8 |

|

time when dust no longer adheres [min] |

40 |

40 |

30 |

|

Structure |

thin |

thick |

thin |

|

Flow |

bad |

good |

very good |

(1) for a coating of 100 μm thickness according to ISO 6504-3

(2) according to EN ISO 2813 (at the angle of 60°)

(3) viscometer, spindle 5/speed 20

Salta S paint – main advantages

Perfect for difficult locations – the ideal solution for façades of buildings located nearby forests, parks and green areas. Due to its high pH, the paint prevents from growth of lichens and mosses.

Excellent water vapour permeability – in other words, the paint has very low diffusion resistance which makes it the most suitable solution for walls insulated with thermal insulation systems based on mineral wool.

Mineral origin – allows for renovating and painting façades of heritage buildings.

Superb operating parameters – facilitate the application – has great opacity, does not splash during work.

Convenient packaging – oval shape of the bucket allows for painting directly from it; there is no need for pouring the paint into another vessel.

Original text: Łukasz Kulczycki, Paweł Karpiński, ATLAS Group

English text: Piotr Marciniak, ATLAS Group