- Products

- Systems

- Tools & Services

News

Tiles loosening – defect under investigation

Case 1. The investor observed tiles on a terrace which loosed off after two years of operation.

Defect

Although the adhesive was hard, it stuck firmly to the tile and was applied correctly upon the surface with a notched trowel, the tiles became loose.

Diagnosis

The first reason for loose tiles was lack of proper priming of the substrate which consisted of some old tiles. In addition, the loosening of tiles in the eave area was caused (or was caused most of all) by lack of proper forming of the flashing. In result water penetrated beneath the tile.

Solution

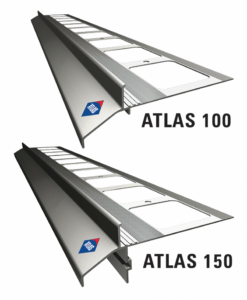

Unfortunately, repair did not consist in repeated tiling only. In fact, it was much more than that, because at first it was decided to hammer off all the terrace layers up to the reinforced concrete slab. Then each layer was re-created with the use of ATLAS 100 system of terrace eaves profiles. There was no other way to ensure long-term, problem-free operation of the terrace.

ALUMINIUM EAVES PROFILES

ATLAS 100

ATLAS 100

Ensure tightness of the eave area of terraces, balconies and other horizontal structural elements finished with ceramic tiles.

Provide efficient drainage of rainwater.

Thick varnish coating (70 μm) provides very good anticorrosive protection. In general, the thickness of coating of other manufacturers profiles is 30-35 μm.

Wide range of supplemental accessories – inner and outer corners and finishes.

Quick installation of custom orders concerning profiles in any RAL colour.

Case 2. Loosening of tiles off OSB was observed even before the work was completed.

Defect

The tiles with bonded adhesive coat fell off the wall a few days after installation (works in a bathroom have not ended yet). The adhesive was properly applied upon the substrate with a notched trowel. The adhesive was hard and bonded firmly to the tile.

Diagnosis

The reason for this defect was lack of proper priming of the OSB, which is a “difficult substrate”. Difficult substrates require special treatment in this regard.

Solution

When planning to bond tiles to OSB, one must attach them securely, so that they would not bent and fault under the designed load. The substrate layers arrangement, including OSB, should be designed and constructed in order to prevent deformation of screed, which in result could cause the destruction of cladding. After installation, the OSB should be grinded and dusted. It is recommended to cover it with ATLAS Woder W or ATLAS Woder E membranes, in order to protect it from moisture and to improve the adhesive bonding. As a contact layer, used only in view of adhesion improvement, one can use ATLAS Cerplast or ATLAS Grunto-Plast. Preparations of this type, due to high content of resins, permanently bond to low absorbable substrates. In addition, they form a layer which provides excellent bonding for adhesives.

All loose tiles and the adhesive coat which only partly bonded to the OSB were removed. Then the entire surface was grinded (OSB got more rough), dusted and coated with ATLAS Woder W damp proofing.

After 24 hours, the tiles were bonded with ATLAS Plus adhesive. OSB was firmly attached to the substrate, so the durability of facing was not threatened.

DEFORMABLE S1 ADHESIVE

ATLAS PLUS

ATLAS PLUS

Enables fixing tiles on difficult substrates – OSB, plasterboards, terrazzo, “tile on tile” as well as strongly bonded paint coatings (e.g. oil paint dado).

Ideal for tiles exposed to deformation – on balconies, terraces, façades, fireplaces, floor and wall heating, wooden ceilings, plasterboards, flexible waterproofing of Woder E, Woder W or Woder Duo type.

For fixing of wide range of tiles – small, medium and large size; of medium absorption; ceramic, cement and stoneware.

Reduced dusting – much less harmful application conditions.

Reduced slip – enables fixing tiles from top to bottom.

PRIMING MASS

ATLAS CERPLAST

ATLAS CERPLAST

For indoor and outdoor use.

Improves bonding to the substrate and strengthens it.

Limits and unifies substrate absorption.

Facilitates application and texture forming of the subsequent layers.

In case of outdoor application, it forms a temporary protection of a façade – protects the non-plastered façade against weather conditions for half a year.

It is available in 4 colours: white, clinker, brown and graphite. In addition, 15 kg and 25 kg packaging are also available in sandy and grey colours and in 400 SAH colours (to be prepared on Atlas tinting machines).

Case 3. During grouting it was observed that the tiles did not bond to the adhesive at all.

Defect

Examination showed that the adhesive did not bond to several tiles lying next to each other – after they were lifted, it occurred that they were completely clean as if they had not been bonded at all. In contrast, the adhesive firmly bonded to the substrate on the entire surface. The adhesive appearance indicated that it was applied with a notched trowel, but the grooves were only slightly deformed. Most importantly, the adhesive was hard and fully bonded.

Diagnosis

Tiles were not properly pressed against the applied adhesive or open time was exceeded. As the tiles stuck well on the remaining surface, we can assume that the contractor kept strictly the given open time (the outer surface of the applied coating had not yet begun to harden) and prevented the adhesive from drying too quickly. Poor quality of adhesive was also excluded from potential reasons of defect – the tile of the same batch was bonded to the substrate in another room, then the contractor tried to detach it after 48 hours. He was not able to do this – the tile strongly bonded to the adhesive and the adhesive firmly bonded to the substrate. To sum up, the reason for the defect is simple: a tiler did not press the particular tile strong enough against the applied adhesive – firstly he applied too little adhesive upon the substrate and in result he could not press the tiles properly as he would not obtain an even facing surface. The negative effect could be also intensified due to the fact that the adhesive was applied only upon the substrate (with a notched trowel) and not upon a tile.

Solution

The tiles were carefully tapped. Those which produced thuds during tapping were hammered off. Then the adhesive was removed and the missing tiles have been purchased (some of the tiles cracked during removal) and bonded keeping the appropriate adhesive thickness. In case of floors, it is recommended to use combined method or self-spreading adhesive, e.g. ATLAS Plus Mega or ATLAS Plus Mega White.

DEFORMABLE S1 ADHESIVE OF C2E TYPE FOR LARGE SIZE FLOOR TILES

ATLAS PLUS MEGA

ATLAS PLUS MEGA

Very wide range of thickness (4-20 mm of thickness) – levels the substrate and fixes tiles at the same time; makes it easier to level the facing surface.

High bonding: ≥ 1 N/mm2 – enables to fix the tiles firmly even to difficult substrates.

Deformable, highly elastic.

Self-spreading – perfectly fills entire space beneath a tile and therefore eliminates air voids which could be filled with water (freezing water causes detaching of tiles).

Provides complete support for large size tiles – eliminates the possibility of cracking

WHITE, DEFORMABLE S1 ADHESIVE OF C2E TYPE FOR LARGE SIZE FLOOR TILES

ATLAS PLUS MEGA WHITE

ATLAS PLUS MEGA WHITE

White colour – does not cause the discolouration of the absorptive tiles, e.g. marble or polished porcelain tiles.

Very wide range of thickness (4-20 mm of thickness) – levels the substrate and fixes tiles at the same time; makes it easier to level the facing surface.

High bonding: ≥ 1 N/mm2 – enables to fix the tiles firmly even to difficult substrates.

Deformable, highly elastic.

Self-spreading – perfectly fills entire space beneath a tile and therefore eliminates air voids which could be filled with water (freezing water causes detaching of tiles).

Case 4. The tiler observed the tiles loosening off the substrate, the adhesive did not bond to the substrate.

Defect

The tile detached from the substrate, it was not a problem to lift it. The open pit showed that the adhesive stuck perfectly to the tile. What is more, the combined method was implemented during the tiling. This method combined two adhesive applications: first – upon the substrate using a notched trowel and second – upon a tile. The adhesive on a tile was hard – it proved that the mortar bonded correctly.

Diagnosis

The reasons for this situation should be sought in the preparation of the substrate. The photo shows only pieces of mesh, which indicates that the substrate was already in very poor condition before tiling and someone tried to deal with it. The idea of embedding the mesh in a layer of repair mortar was not bad, but the actual execution was awful. Contractor admitted that “there was no space” for the leveling layer of suitable thickness. Therefore, he spread the mesh over the existing floor and coated it with the adhesive very thin layer. The thickness of this “repair” layer was only 1 mm. So was the thickness of the mesh. One should ask: where is the coating of such provisional reinforcement?

Solution

Properly done work should be as follows:

1. Remove loose pieces of the substrate (mechanically or manually with a chisel) – it was not done;

2. Prime the substrate with an emulsion which reduces the absorption, e.g. ATLAS Uni-Grunt or ATLAS Grunto-Plast – it was done;

3. Apply the leveling layer of approx. 4 mm thickness and alternatively embed the reinforcing mesh in it – it was done, but too thin layer was used. Moreover, according to contractor’s words, the adhesive used for filling had a thinner consistency (despite the fact that it is obligatory to use given amount of batched water) so that it was easier to spread it over the mesh;

4. Bond the tiles with a self-spreading adhesive (e.g. ATLAS Plus Mega or Atlas Plus Mega White) or combined method (e.g. ATLAS ELASTYK) – it was done.

In result, it was necessary to remove all the tiles and to bond new ones after careful repair of the surface.

FAST DRYING PRIMING EMULSION

A TLAS UNI-GRUNT

TLAS UNI-GRUNT

Reduces the substrate absorption – improves the conditions for mortars binding and contributes to the specified technical parameters.

Very short drying time – the adhesive can be applied already after 2 hours since priming.

Strengthens the surface of primed mineral substrates – permeates the surface, strengthens it and improves its load capacity.

Very efficient.

BONDING LAYER FOR DIFFICULT SUBSTRATES

ATLAS GRUNTO-PLAST

ATLAS GRUNTO-PLAST

Universal primer for difficult substrates – improves the bonding of adhesives, waterproofing and finishing coats to substrates of low absorptivity, to extremely smooth substrates, or coated with residues of old PVC adhesives, paints, etc.

Improves the adhesive bonding to the substrate – adheres firmly both to the substrate and to the newly applied layers.

Contains aggregate – forms rough surface when dry – it significantly boosts the joint area between old and new layer which in result improves the bonding between them.

Well bonding – the adhesion to concrete is min. 1.0 MPa.

Original text: Piotr Idzikowski, ATLAS Group

English text: Piotr Marciniak, Michał Gosławski, ATLAS Group